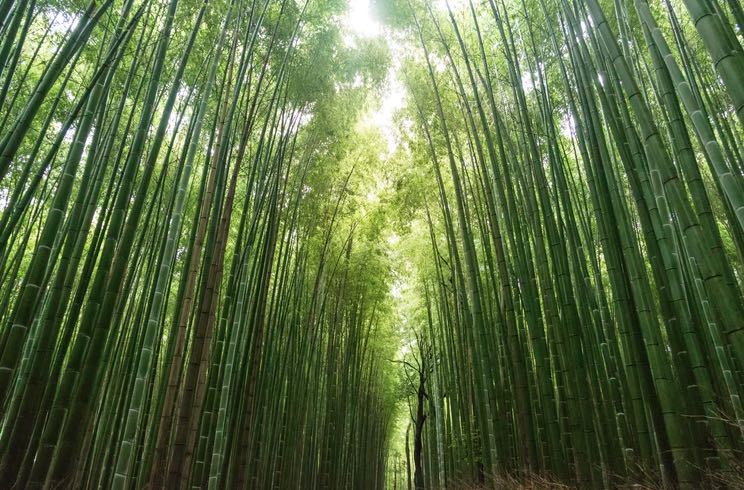

Bamboo is the most rapidly expanding plant species on the planet and also happens to be completely organic. Due to its low water and pesticide needs, as well as its low carbon footprint, bamboo is a sustainable crop that can be produced in a wide variety of climates and regions. As far as eco-friendly fabrics go, bamboo cloth is currently the most on-trend option in the garment industry.

A healthy bamboo plant can add up to four feet to its height every single day. In addition, the bamboo plant produces 35% more oxygen than other trees of the same height. Considering how quickly it grows, bamboo only takes seven years to reach maturity. It has a massive root system from which it perpetually sends up new growth, thus it can be left alone without replanting. The soil is improved and erosion is reduced as a result.

It's no secret that many individuals lack access to less expensive alternatives to high-end fabrics because the fashion industry relies so heavily on cotton and other textiles that are expensive to create and can then be paid considerably more for. The bamboo fabric, however, is stronger than most others, is antibacterial, is insulating, and is softer than cotton and on par with cashmere. In a period of steadily increasing gas prices and general inflation, it is a priceless economic asset.

What Is Bamboo Fabric?

The rapidly expanding grass has gained popularity as a sustainable crop. Bamboo is currently trending as a material of choice for many industries. Is bamboo really the miracle crop many people claim it to be, considering that claims linked with it have been disputed? These claims include that bamboo is sustainable, that it provides UV protection, and that it has anti-bacterial characteristics. How long may bamboo be used before it needs replacing?

There are many various types of bamboo-based textiles, and the phrase "bamboo fabric" is used to describe them all. Bamboo has been used to create textiles for thousands of years, but it is only in recent decades that the method of turning this durable and rapidly reproducing wood into textiles has been refined.

Bamboo cloth has a complicated history. Some fabrics are made in an ethical and sustainable way, while others could be harmful to the environment or the people who make them. It's crucial to familiarise yourself with the textile business surrounding bamboo so that you can make an informed decision when purchasing bamboo fabric.

How Is Bamboo Fabric Made?

Bamboo textiles can be constructed in a variety of ways, each optimised for a certain type of cloth.Bamboo viscose constitutes the vast majority of bamboo fabric produced worldwide due to its low production cost. Despite having detrimental impacts on the environment and causing safety issues in the workplace, bamboo viscose is widely used.

We need to learn more about the manufacturing of rayon textiles like this before we can make sense of these labels.

The supple bamboo fabrics you find in stores are all rayon, which is a family of synthetic fibres. Lyocell, modal, and rayon may sound like synthetic materials due to their plastic-like names, but they are not (petroleum-based like nylon or polyester). Since they are not made from a natural fibre (like wool) or a natural fibre source (like cotton, flax, jute, or hemp), their production method is not entirely natural (linen). Since these fibres are "regenerated," they stand for a transitional phase.

For starters, there's cellulose, the natural polymer found in every plant cell. It is the cellulose in rayon, modal, and lyocell that gives these materials their luxurious sheen. Plants (often trees but more recently bamboo) have their cellulose removed by taking the woody section of the plant and crushing it, followed by mixing it with either a natural enzyme or poisonous chemicals to make a slurry.

After being fed into a spinneret, this slurry is extruded via a device like a showerhead, where it is spun into the soft fibres that will eventually be transformed (regenerated) into nearly pure cellulose. The term "viscose process" was used to describe this phenomenon. We then dry, grind, and fluff the fibres. To create fabrics from them, they are first coloured, then spun into thread.

Production

In terms of cost, bamboo fabric production is superior to that of other textiles. When the bamboo plants are young, everything is only beginning. Some of the plants can reach maturity in less than three months, which is far faster than the growth rate of conventional cotton. Even if it's difficult for other plants to thrive there, bamboo can. It thrives in soil that has been depleted by erosion or desertification and is located close to sources of water. It's also adaptable enough to survive in drought-prone regions.

Growing Bamboo

It seems promising at first. Since it is a fast-growing grass that can self-regenerate from its own roots, bamboo doesn't need to be replanted very often and can be a very sustainable crop. The benefits are readily apparent when compared to cotton farming, which calls for substantial amounts of water, pesticides, and labour.

Not so fast! There are a few things to think about before you go shopping for new clothes. First of all, just because bamboo grows quickly and needs no pesticides doesn't guarantee it's being cultivated in a sustainable manner. Despite China being the world's largest producer of bamboo, we know little about the scale of its harvest or the extent to which land is being cleared there. Despite the fact that bamboo doesn't require pesticides, that doesn't mean they aren't being utilised to increase yields.

Bamboo requires significantly less water and chemical fertilisers than cotton. Bamboo, unlike cotton, has a natural bio-agent within it (known as bamboo Kun). This bamboo Kun not only prevents diseases from wreaking havoc on the plants, but it also discourages pests from making a meal of the bamboo in the first place. Long-term, this bio-agent will also be responsible for imparting antibacterial qualities to bamboo fabric.

To create bamboo fabric, the harvested bamboo plant is first processed into bamboo pulp. This method significantly reduces the amount of water required to produce a textile, especially cotton. After being softened, bleaching the fabric without chlorine or other costly chemicals enables it to take on any shade desired. The cost of dying bamboo is lower than comparable techniques. When compared to dying other textiles, less water and less toxic chemicals are needed.

Products

Creating Fabric

Yes, you're right, bamboo has its drawbacks, but it's more eco-friendly and requires fewer chemicals than cotton, right? Although this is likely to be correct throughout the growing stage, it is not necessarily so during the production phase. You may weave bamboo in a number of different ways.

The initial step is to separate the bamboo's individual fibres and spin them into thread. The resulting fabric is often referred to as "bamboo linen," and it has a slightly gritty texture. The process of making this "linen" is time-consuming and costly, and the resulting fabric is too stiff to be used in the kinds of delicate, personal goods that have made bamboo so popular.

The second, more common procedure is what's utilised to create the silky smooth bamboo fabric used for things like sheets, undergarments, and more. Similar to the chemical method used to transform wood chips into rayon, this "bamboo rayon" is manufactured. Now we get into the thorny issue of bamboo's long-term viability. Essentially, rayon is a byproduct of a chemical reaction between two raw materials. In the end, the output of this procedure is a hybrid between natural and synthetic. Cotton, wood, or even bamboo can all be used as a source of the cellulose. This means that the processing of soft bamboo fabric is practically identical to that of semi-natural rayon.

Commonly, bamboo rayon is manufactured by the viscose process, which entails dissolving cellulose material like bamboo in a chemical solution to create a pulpy viscous substance. After being "spun" into fibres, these are used to create yarns and textiles. Human health is put at risk by the usage of these substances in this process. As much as fifty percent of the hazardous waste created during rayon production (including the bamboo variant) is lost forever and released into the environment.

Products crafted from bamboo cloth are just as cost-effective as the manufacturing method itself. Bamboo fabric delivers more in a product than cotton fabric, which is why many bamboo items are more cost-effective. Premium cotton sheets with a high thread count are among the most expensive textiles available. The luxurious comfort of the bedding makes these items much sought after despite their high price. While high thread count cotton sheets are luxuriously smooth and comfortable, the shine and drape of bamboo bedding are reminiscent of more expensive silk sheets without the hefty price tag. Bamboo sheets are better for persons who are prone to disease and have allergies because they are anti-bacterial.

The same can be said about other bamboo apparel, including shirts and socks, which are great for keeping you fresh and cool in the summer heat. In comparison to cotton, bamboo cloth has superior absorbency and drying time. In other words, it swiftly dries the sweat and causes unpleasant odours after being absorbed by it. With its moisture-wicking properties and ability to resist sticking, bamboo apparel is ideal for hot climates. These garments are more cost-effective in the long run than cotton because they may be worn multiple times before needing to be replaced.

It's clear that bamboo products are making a splash everywhere they go. Bamboo fabric is superior to cotton in terms of cost and renewable resources, from the way it is cultivated through the processing to the items created from it. It is expected that bamboo will be utilised significantly more frequently in the future.

While bamboo has several desirable traits, such as being antibacterial and resistant to ultraviolet light, there is little proof that these characteristics survive the processing required to turn bamboo into textiles.

Good news! Lyocell (trademarked as TENCEL) is a comparable fabric that uses a closed-loop procedure to recover and recycle 99 percent of the chemical solution. With its "European Award for the Environment," the European Union recognises Tencel's environmentally friendly production process and its use of sustainably farmed eucalyptus trees. Fabric made from bamboo through the lyocell technique is still quite uncommon.

FAQs About Bamboo Fabric

Growing bamboo is typically gentler on the environment than growing cotton, but processing that bamboo into fabric usually uses chemical agents. While bamboo sheets tend to cost a bit more than most cotton sets, Egyptian cotton sheets are usually significantly more expensive than bamboo sets.

Bamboo viscose outperforms other fabrics in many ways, and one noticeable difference is the longevity of the material. Bamboo fabric can last a decade, or even longer if it's well taken care of.

Bamboo products are also advertised for their antimicrobial qualities, which helps reduce and destroy odor-causing bacteria. Bamboo fabric is also breathable and said to be more absorbent and stronger than cotton.

Bamboo fabric is soft because it contains two different types of fibers. One of these fibers is mechanical and the other is chemical. The chemical fibers are used to make bamboo bedding, and they're one of the reasons that bamboo bedding is so soft.

When used in fabric, bamboo naturally wicks away moisture from the body, keeping sweat off your skin and helping you stay cool and dry. Bamboo textile also dries very quickly, so you don't have to worry about sitting around in a wet shirt soaked in sweat after your workout.

Where Is Bamboo Fabric Produced?

Fabric made from bamboo has been made in East Asia for centuries, perhaps even millennia. Cultural groups in India and China, for example, have been making this fabric for centuries, and rural areas of India still celebrate the material with annual festivals dedicated to bamboo fabric.

Since cultivating bamboo is less taxing on the environment than other types of wood, it has seen a rise in production all around the globe. As a result of its adaptability, this wood is increasingly being produced in the United States and Europe, two traditionally unsuitable regions. Since this is the case, nearly every developed or semi-developed nation produces or exports bamboo cloth.

However, China is the world leader in producing this crop. After all, bamboo has been a part of Chinese culture for millennia, and it has long been a favourite material for creating textile products in this area, so this economic fact is, in some respects, only natural.

One reason why bamboo fabric is so popular in China is because of its low cost. China's environmental standards and human rights violations in the consumer goods production sector have made it increasingly attractive to foreign textile businesses since the late 1970s.

Because of China's continued low production costs, many companies that specialise in bamboo fabric have set up shop there. Producing this textile crop in China causes more environmental damage than is necessary since Chinese enterprises are not strongly incentivized to cultivate their products ethically or sustainably. However, it cannot be denied that the cost to manufacture bamboo fabric in this country is little.

India, Pakistan, and Indonesia are other significant suppliers of this cloth. The United States also produces a sizable amount of this fabric, but since it is mostly used for domestic consumption, it does not significantly increase U.S. exports.

Under optimal conditions, bamboo is an extremely resilient crop (and it often is). On the other hand, the vast majority of commercially available bamboo fabrics are actually rayon, a type of synthetic fibre whose production requires a lengthy and toxic chemical procedure.

Lyocell is a more eco-friendly option that has a smaller environmental footprint, however bamboo lyocell goods are difficult to come by. Consider eco-friendly textiles like organically farmed hemp for certain garments. When deciding between conventional cotton and organic cotton, the former is almost always the more eco-friendly option (especially the fabric dying process).

The vast majority of "bamboo" goods on the market are actually rayon, produced with a lot of harmful chemicals and probably lacking the same beneficial characteristics as the uncooked bamboo plant. The production of bamboo fabric is less expensive than that of cotton (and thus avoids the extensive use of pesticides in non-organic cotton production) and less chemically intensive than that of polyester; however, bamboo fabric is unfortunately not the perfect answer to all of our ethical clothing conundrums; in fact, European NGO Made-In claims that "bamboo fabric is not the perfect answer to all of our ethical clothing conundrums." Bamboo viscose receives a D on By's grading range from A+ to E+, the same as regular cotton. According to the Los Angeles Times, bamboo "has been thoroughly rejected as a [environmentally] alternative supply."

When compared to cotton, bamboo is more promising as a sustainable crop. However, much effort is put into developing and making accessible low-cost and environmentally sustainable methods of making the luxuriously smooth bamboo fabrics of our dreams.

How Does Bamboo Fabric Impact the Environment?

Fabrics made from bamboo are often promoted as "green" because of their low environmental impact. For example, bamboo requires almost no maintenance, develops rapidly, and thrives in soils that would otherwise be unsuitable for other types of crops. It is up to individual bamboo producers to guarantee that their harvest is obtained in a sustainable manner, but in theory, the environmental impact of producing bamboo is rather modest.

Although bamboo has environmental benefits, the modern demand for it has prompted several Chinese manufacturers to clear-cut forests in order to plant bamboo. However, the Chinese Communist Party enacted rules in the late 1990s outlawing such conduct.

While modern bamboo growing may have a low environmental impact, the production of bamboo viscose is anything from sustainable. However, several harmful chemicals are utilised to convert raw bamboo into the cellulose that is used to produce rayon, therefore there is a small but real risk of toxic chemical exposure for consumers who wear or use bamboo fabric.

For instance, lye is typically discarded after preparing bamboo wood for cellulose extraction. In addition, carbon disulphide is used throughout the process of making rayon, and this deadly chemical can never be recovered after it has been used.

Manufacturing bamboo in emerging economies like China has been met with much debate. Carbon disulphide gas is released during the manufacture of bamboo rayon, and many factories in China subject their workers to this danger.

Carbon disulphide is toxic to the nervous system and can harm other body systems as well. It has been linked to insanity, liver damage, coma, blindness, and heart attacks among workers who have been exposed to this substance. Some firms may take precautions to safeguard their employees from carbon disulphide, however the Chinese government's regulatory limits for this material are much higher than the safety threshold advised by medical scientists.

Unfortunately, most bamboo fabrics are rayon, which means that production methods that are harmful to the environment are used. It's worth noting that environmentally friendly processes can be used to create authentic bamboo fibre. Manufacturers of bamboo fabrics recommend avoiding bamboo viscose in favour of either genuine bamboo fibres or lyocell-like bamboo cellulose fabrics.

What Are the Benefits and Drawbacks of Bamboo Fabric?

Benefits

When compared to more conventional fabric-making materials, this one offers several advantages.

- Bamboo fibre textiles are more luxurious than cotton and as smooth as silk.

- It's grown without the use of chemicals or pesticides, so it's naturally antibacterial and hypoallergenic.

- Fast moisture absorption means you stay dry and fresh all day. Useful as a part of your workout attire.

- Clothing made from 100% pure bamboo can dry in half the time it takes cotton.

- As bamboo fabrics are breathable and naturally insulating, you can wear them all year-round.

- The pulp of the bamboo plant is used to make the fabric. No chlorine is used in the bleaching process. It's not difficult to change the colour of bamboo fabric, and it can be done with less chemicals and less water than traditional dyes.

- Planting bamboo and having it grow again is a very sustainable practise. Due to its rapid growth, bamboo can be harvested after only four years. It self-seeds, so there's no need to replant it. Furthermore, it effectively transforms a considerable amount of carbon dioxide into oxygen.

- It's simple to cultivate bamboo using just natural methods. In most cases, insecticides and fertilisers are unnecessary. It may also survive in dry conditions without requiring constant watering.

- Fabrics made from bamboo have a natural resistance to microorganisms. It's also great for people with allergies because it's hypoallergenic. It's been found that many people who are allergic to other textiles can wear bamboo without any adverse effects.

- Like cotton, bamboo has a natural ability to wick away moisture. By drawing moisture away from the skin, it helps keep you at a comfortable temperature all day long. Bamboo won't stick to you like other textiles will when you're hot and sweaty. It's useful for maintaining a comfortable body temperature while sleeping in hot climates.

- To put it simply, bamboo can be composted. Since bamboo is a plant, you may recycle it into compost and use the material to create something new when it finally wears out. Unlike conventional fabrics, those made from bamboo can be recycled endlessly.

- This fabric is quite comfortable. The smoothness it imparts has been compared to that of silk by some.

Drawbacks

It stands to reason that there must be some drawbacks to any potential benefit. There are numerous benefits to bamboo fabric, but you need to think about how you will be wearing it and how you will be caring for it.

- Although bamboo has natural antibacterial characteristics, its absorbent fibres actually promote microbial growth because they soak up so much perspiration.

- There is some evidence that bamboo fibres let UV light through, making bamboo clothing a poor choice for outdoor use.

- Bamboo is currently trending and will likely be more expensive than cotton, which is a major issue for many consumers.

- This plant is known to spread quickly. Growing it in a non-natural environment increases the risk of it taking over and outcompeting native species.

- Special care may be needed when washing bamboo clothes because they shrink more than cotton.

- As with other materials, bamboo fabric tends to wrinkle easily. Bamboo may not be the best option for your fabric depending on how you plan to put it to use.

Conclusion

Bamboo is the most rapidly expanding plant species on the planet and also happens to be completely organic. A healthy bamboo plant can add up to four feet to its height every single day. Bamboo fabric is stronger than most others, is antibacterial, is insulating, and softer than cotton. Bamboo textiles can be constructed in a variety of ways, each optimised for a certain type of cloth. Lyocell, modal, and rayon may sound like synthetic materials due to their plastic-like names, but they are not (petroleum-based like nylon or polyester).

Since these fibres are "regenerated," they stand for a transitional phase. Bamboo is a fast-growing grass that can self-regenerate from its own roots. The benefits are readily apparent when compared to cotton farming, which calls for substantial amounts of water, pesticides, and labour. Bamboo requires significantly less water and chemical fertilisers than cotton. The processing of soft bamboo fabric is practically identical to that of semi-natural rayon.

Bamboo fabric delivers more in a product than cotton fabric, which is why many bamboo items are more cost-effective. With its moisture-wicking properties and ability to resist sticking, bamboo apparel is ideal for hot climates. Bamboo fabric is superior to cotton in terms of cost and renewable resources, from the way it is cultivated through the processing to the items created from it. Lyocell (trademarked as TENCEL) is a comparable fabric that uses a closed-loop procedure to recover and recycle 99 percent of the chemical solution. The vast majority of commercially available bamboo fabrics are actually rayon, a type of synthetic fibre whose production requires a lengthy and toxic chemical procedure.

Bamboo viscose receives a D on By's grading range from A+ to E+. The production of bamboo fabric is less expensive than that of cotton (and thus avoids the extensive use of pesticides in non-organic cotton production). Bamboo fibre textiles are more luxurious than cotton and as smooth as silk. It's grown without the use of chemicals or pesticides, so it's naturally antibacterial and hypoallergenic. Manufacturers recommend avoiding bamboo viscose in favour of either genuine bamboo fibres or lyocell-like bamboo cellulose fabrics.

Fabrics made from bamboo have a natural resistance to microorganisms. Many people who are allergic to other textiles can wear bamboo without any adverse effects. Since bamboo is a plant, you may recycle it into compost and use the material to create something new when it finally wears out. There are numerous benefits to bamboo fabric, but you need to think about how you will be wearing it. Growing it in a non-natural environment increases the risk of it taking over and outcompeting native species. Special care may be needed when washing bamboo clothes because they shrink more than cotton.

Content Summary

- Bamboo is the most rapidly expanding plant species on the planet and also happens to be completely organic.

- Due to its low water and pesticide needs, as well as its low carbon footprint, bamboo is a sustainable crop that can be produced in a wide variety of climates and regions.

- As far as eco-friendly fabrics go, bamboo cloth is currently the most on-trend option in the garment industry.

- The bamboo fabric, however, is stronger than most others, is antibacterial, is insulating, and is softer than cotton and on par with cashmere.

- The rapidly expanding grass has gained popularity as a sustainable crop.

- Bamboo is currently trending as a material of choice for many industries.

- These claims include that bamboo is sustainable, that it provides UV protection, and that it has anti-bacterial characteristics.

- There are many various types of bamboo-based textiles, and the phrase "bamboo fabric" is used to describe them all.

- Bamboo has been used to create textiles for thousands of years, but it is only in recent decades that the method of turning this durable and rapidly reproducing wood into textiles has been refined.

- Some fabrics are made in an ethical and sustainable way, while others could be harmful to the environment or the people who make them.

It's crucial to familiarise yourself with the textile business surrounding bamboo so that you can make an informed decision when purchasing bamboo fabric. - Bamboo viscose constitutes the vast majority of bamboo fabric produced worldwide due to its low production cost.

- We need to learn more about the manufacturing of rayon textiles like this before we can make sense of these labels.

- The supple bamboo fabrics you find in stores are all rayon, which is a family of synthetic fibres.

- It is the cellulose in rayon, modal, and lyocell that gives these materials their luxurious sheen.

- In terms of cost, bamboo fabric production is superior to that of other textiles.

- Since it is a fast-growing grass that can self-regenerate from its own roots, bamboo doesn't need to be replanted very often and can be a very sustainable crop.

- The benefits are readily apparent when compared to cotton farming, which calls for substantial amounts of water, pesticides, and labour.

- First of all, just because bamboo grows quickly and needs no pesticides doesn't guarantee it's being cultivated in a sustainable manner.

- Despite China being the world's largest producer of bamboo, we know little about the scale of its harvest or the extent to which land is being cleared there.

- Despite the fact that bamboo doesn't require pesticides, that doesn't mean they aren't being utilised to increase yields.

- Bamboo requires significantly less water and chemical fertilisers than cotton.

- Bamboo, unlike cotton, has a natural bio-agent within it (known as bamboo Kun).

- To create bamboo fabric, the harvested bamboo plant is first processed into bamboo pulp.

- Yes, you're right, bamboo has its drawbacks, but it's more eco-friendly and requires fewer chemicals than cotton, right?

- The second, more common procedure is what's utilised to create the silky smooth bamboo fabric used for things like sheets, undergarments, and more.

- Similar to the chemical method used to transform wood chips into rayon, this "bamboo rayon" is manufactured.

- Now we get into the thorny issue of bamboo's long-term viability.

- This means that the processing of soft bamboo fabric is practically identical to that of semi-natural rayon.

- Commonly, bamboo rayon is manufactured by the viscose process, which entails dissolving cellulose material like bamboo in a chemical solution to create a pulpy viscous substance.

- Products crafted from bamboo cloth are just as cost-effective as the manufacturing method itself.

- Bamboo fabric delivers more in a product than cotton fabric, which is why many bamboo items are more cost-effective.

- Premium cotton sheets with a high thread count are among the most expensive textiles available.

- In comparison to cotton, bamboo cloth has superior absorbency and drying time.

- Bamboo fabric is superior to cotton in terms of cost and renewable resources, from the way it is cultivated through the processing to the items created from it.

- Fabric made from bamboo through the lyocell technique is still quite uncommon.

- Fabric made from bamboo has been made in East Asia for centuries, perhaps even millennia.

- However, China is the world leader in producing this crop.

- After all, bamboo has been a part of Chinese culture for millennia, and it has long been a favourite material for creating textile products in this area, so this economic fact is, in some respects, only natural.

- One reason why bamboo fabric is so popular in China is because of its low cost.

- Because of China's continued low production costs, many companies that specialise in bamboo fabric have set up shop there.

- However, it cannot be denied that the cost to manufacture bamboo fabric in this country is little.

- Lyocell is a more eco-friendly option that has a smaller environmental footprint, however bamboo lyocell goods are difficult to come by.

- Consider eco-friendly textiles like organically farmed hemp for certain garments.

- The production of bamboo fabric is less expensive than that of cotton (and thus avoids the extensive use of pesticides in non-organic cotton production) and less chemically intensive than that of polyester; however, bamboo fabric is unfortunately not the perfect answer to all of our ethical clothing conundrums; in fact, European NGO Made-In claims that "bamboo fabric is not the perfect answer to all of our ethical clothing conundrums."

- When compared to cotton, bamboo is more promising as a sustainable crop.

- However, much effort is put into developing and making accessible low-cost and environmentally sustainable methods of making the luxuriously smooth bamboo fabrics of our dreams.

- Fabrics made from bamboo are often promoted as "green" because of their low environmental impact.

- Although bamboo has environmental benefits, the modern demand for it has prompted several Chinese manufacturers to clear-cut forests in order to plant bamboo.

- While modern bamboo growing may have a low environmental impact, the production of bamboo viscose is anything from sustainable.

- However, several harmful chemicals are utilised to convert raw bamboo into the cellulose that is used to produce rayon, therefore there is a small but real risk of toxic chemical exposure for consumers who wear or use bamboo fabric.

- In addition, carbon disulphide is used throughout the process of making rayon, and this deadly chemical can never be recovered after it has been used.

- Carbon disulphide gas is released during the manufacture of bamboo rayon, and many factories in China subject their workers to this danger.

- Carbon disulphide is toxic to the nervous system and can harm other body systems as well.

- Unfortunately, most bamboo fabrics are rayon, which means that production methods that are harmful to the environment are used.

- It's worth noting that environmentally friendly processes can be used to create authentic bamboo fibre.

- Manufacturers of bamboo fabrics recommend avoiding bamboo viscose in favour of either genuine bamboo fibres or lyocell-like bamboo cellulose fabrics.

- It's not difficult to change the colour of bamboo fabric, and it can be done with less chemicals and less water than traditional dyes.

- Planting bamboo and having it grow again is a very sustainable practise.

- Due to its rapid growth, bamboo can be harvested after only four years.

- It's simple to cultivate bamboo using just natural methods.

- Fabrics made from bamboo have a natural resistance to microorganisms.

- It's also great for people with allergies because it's hypoallergenic.

- Like cotton, bamboo has a natural ability to wick away moisture.

- By drawing moisture away from the skin, it helps keep you at a comfortable temperature all day long.

- It's useful for maintaining a comfortable body temperature while sleeping in hot climates.

- To put it simply, bamboo can be composted.

- Since bamboo is a plant, you may recycle it into compost and use the material to create something new when it finally wears out.

- Unlike conventional fabrics, those made from bamboo can be recycled endlessly.

- This fabric is quite comfortable.

- There are numerous benefits to bamboo fabric, but you need to think about how you will be wearing it and how you will be caring for it.

- There is some evidence that bamboo fibres let UV light through, making bamboo clothing a poor choice for outdoor use.

- Special care may be needed when washing bamboo clothes because they shrink more than cotton.

- As with other materials, bamboo fabric tends to wrinkle easily.

- Bamboo may not be the best option for your fabric depending on how you plan to put it to use.